Tesla (NASDAQ: TSLA) recently revealed its unusual strategy of purchasing materials for electric vehicle battery production – lithium, nickel, and cobalt – directly from mines as opposed to through its cell suppliers. This strategy will be crucial as businesses compete to obtain those minerals for battery production to support the expansion of electric vehicles.

While the majority of Tesla’s battery cells come from suppliers, a sizable portion of the materials used to make those batteries come directly from mines.

With the support of this strategy, Tesla is able to maintain tight ties with the miners of vital minerals, which helps secure supply while enabling the company to continuously monitor quality and assure ethical environmental and social sourcing.

“Direct sourcing from mining companies allows Tesla to engage directly in local contexts instead of having to rely on multiple midstream companies that typically sit between EV makers and mining,” the automaker said in its Impact Report.

In its high-energy density cells, the automaker claims that in 2021, it had directly obtained more than 95% of the lithium hydroxide, 50% of the cobalt, and more than 30% of the nickel. The battery cell producers’ agreements with their own material suppliers provided the remaining funds.

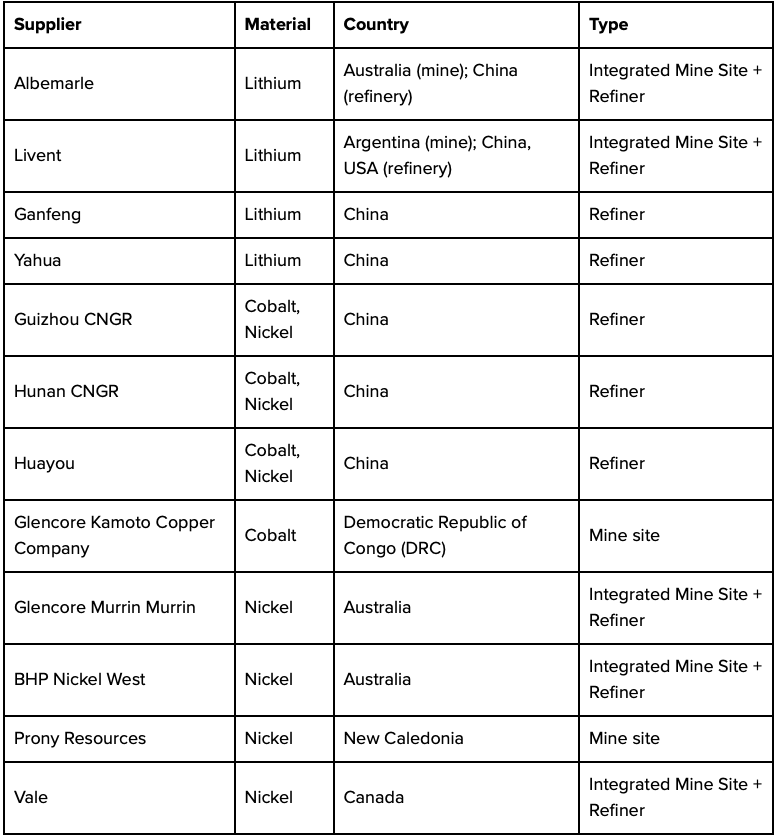

Previously, Tesla disclosed a list of the mining firms providing those minerals, including Albemarle, Glencore, Vale, and BHP.

The company’s Impact Report also makes it plain how concerned Tesla is that mining and its environmental and social impacts are going to become more of a barrier to EV adoption in the future. This is another, less-discussed part of the report.

“Cobalt, lithium and nickel are also ‘minerals’ – in that they are raw materials that are produced through different methods of mining around the world, often concentrated in countries that face socio-economic and environmental challenges,” Tesla added. “As known global reserves are depleted, these minerals are becoming increasingly scarce, and companies look to access resources in more remote and challenging locations to meet global demand.”

Tesla has responded by signing up for the Initiative for Responsible Mining Assurance, and the company’s direct-sourcing strategy also contributes to ensuring that these criteria are followed.

The news comes days after the automaker was reportedly dropping the axe on some battery production jobs at its Shanghai factory, just as the electric carmaker fights through intense price competition in China’s automobile market.

Employees involved in cell assembly lines at the initial phase of the plant, or the 1.0 battery line, were reportedly notified according to a report from Bloomberg.

Information for this story was found via Electrek and the sources mentioned. The author has no securities or affiliations related to the organizations discussed. Not a recommendation to buy or sell. Always do additional research and consult a professional before purchasing a security. The author holds no licenses.