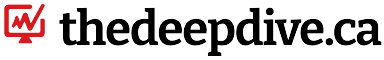

Tesla (Nasdaq: TSLA) CEO Elon Musk announced that the company’s new electric semi truck will not enter high-volume production until the end of next year due to constraints in battery supply.

Despite announcing the start of deliveries of the trucks at the end of last year, the production volume has been limited. Pepsi received the first batch of deliveries in December, three years after it was originally due. The drinkmaker placed their orders shortly after the all-electric Class 8 truck prototype was unveiled in 2017.

Musk did not provide specific details on what he considers higher-volume production during his speech at an energy conference in Austin, Texas. It’s also unclear if this means that the carmaker will make smaller deliveries in between.

There’s nothing new about the delay and the reason behind it. The Semi was originally due out in 2019, but Tesla was only able to complete engineering work on the truck in January 2021 and was on track to begin deliveries then, but production had to be pushed to 2022 due to supply chain problems and the limited availability of the battery cells.

🚨 Musk says no $TSLA Semi till late 2024.

— Motorhead (@BradMunchen) June 13, 2023

The excuse is the same as that in July 2021, when Musk said Semi start of production was delayed till "late 2022": lack of battery cells.

If $TSLA is so cell-constrained, what happens to "muh Megapacks" this year & next? pic.twitter.com/4k9cp8MF1d

The Semi runs on harder to produce lithium-ion batteries with nickel, manganese, and cobalt cathodes (NMC) with a longer, 500-mile (805-kilometer) driving range per charge. At the launch of Master Plan Part 3 in April, the company said that it intends to release what it called the Semi Light but did not give details on the timeline. These “short range” heavy electric trucks will use lithium iron phosphate (LFP) batteries.

LFP batteries have a lower energy density and therefore shorter range per charge. But unlike NMC batteries, LFP batteries are easier and cheaper to produce. Musk said in March that “the vast majority of the heavy lifting for electrification will be iron-based cells.”

RELATED: Ford Announces Access to Tesla EV Charging Network

In January, the company announced the $3.6 billion expansion of the Gigafactory in Nevada to add two new factories, one “a 100 GWh 4680 cell factory (with capacity to produce enough batteries for 1.5 million light duty vehicles annually),” and the other their “first high-volume Semi factory.”

Information for this story was found via The Wall Street Journal, Reuters, Tesla, and the sources and companies mentioned. The author has no securities or affiliations related to the organizations discussed. Not a recommendation to buy or sell. Always do additional research and consult a professional before purchasing a security. The author holds no licenses.